In this short blog, Deborsi Basu, presents about Industry 5.0. He is a graduate student IEEE member,  who is pursuing his Ph.D. degree from G. S. Sanyal School of Telecommunications, IIT Kharagpur, India with the joint collaboration of Vanderbilt University, Nashville, Tennessee, USA.

who is pursuing his Ph.D. degree from G. S. Sanyal School of Telecommunications, IIT Kharagpur, India with the joint collaboration of Vanderbilt University, Nashville, Tennessee, USA.

Introduction to Industry 5.0

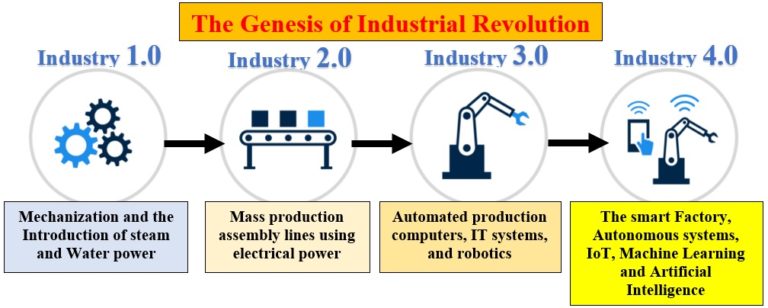

The amplifications of technological advancements transform (e.g AI, ML, Cloud Computing, DL, CNN, DNN) the future industrial aspect completely and an all-new version of Industry has appeared in the market which is also termed as Industry 5.0 or Fourth Industrial Revolution. It is the digitization and automation of conventional manufacturing practices, using advanced technologies that include M2M (Machine to Machine) Communication, Human-Machine Interaction, integrated Internet of Things (IoT). It aims to multiply the productivity by minimizing the human interventions. Industry 5.0 has various categorical visions. Some futurists believe that although Industry 4.0 is targeting to fulfil the advanced demands of end-users, Industry 5.0 is essentially about connecting equipment together, and about the collaboration between humans and machines on the factory floor of lists for the benefits of human-machine collaboration. There will be creative humanization in the production, rather than standard robot production. It will create new employment opportunities. Human workers will play a better role on the factory floor. According to various preliminary researches, Industry 5.0 is a return to the humanization of the factory floor. Rendall (2017) believes that although Germany leads the fourth industrial revolution, North America is in a unique position to lead the next industrial revolution—Industry 5.0. Market experts shared the vision of human-machine collaboration in Industry 5.0 with many others. The world has witnessed a substantial increase in environmental pollution caused by the second industrial revolution. However, unlike the past few decades, the manufacturing industry has become more focused on controlling different aspects of waste generation and management, and reducing the adverse environmental impact of its operations. There are many discussions and posts related to Industry 5.0 on the Internet. Some of the major applications of them are listed below.

Major Applications of Industry 5.0

- Smart Energy Consumptions

- Real-time productivity optimization

- Intelligent IoT (IIoT)

- Self-monitoring and feedback control

- Minimal maintenances

- Digital Market

- Advanced Robotics

- Augmented Reality and Virtual Reality

- Digital Performance Management

- Indoor and Outdoor Automation

- Smart Healthcare and Agriculture

- Improved transportation and communication

Revolutionary Technologies

Industry 5.0 is currently in its growing stage and researchers are continuously working on it. The fundamental aim of the technology is to make the human life better. Though, the new normal condition due to COVID-19 hits the production of latest technology inefficiently but this Industry revolution can be one of the major shields to battle this deadly disease. The implantations of Oxygen Plants, rapid manufacturing of Vaccines, Rapid transportation of essential resources and also provide optimum services to keep people at there home safely will be possible for this revolution.

Future of Industry 5.0

The future of Industry 5.0 is extremely promising. It is expected that this will be a key sword to battle against this deadly disease. Our prime objective must be to support this revolution and apply this advancement for the betterment of humanity. The worldwide effects due to the impact of the amalgamated technologies will change the lifestyle of the mankind as well. Being a modern era researcher, this short article will act as one of the major brainstorming materials for the young minds to contribute by solving the existing challenges caused by Industry 5.0.

**Statements and opinions given in this blog are the expressions of the contributor(s). Responsibility for the content of published articles rests upon the contributor(s), not on the IEEE Communication Society or the IEEE Communications Society Young Professionals.